PVC homoegeneous LVT SPC WPC floor extrusion line

PVC Homogeneous Heart Flooring Leather Production Line

PVC Homogeneous Heart Flooring Leather Production Line is made of different colors of PVC crushed material, adopting even proportion and thermo-pressing.

Because of its environmental protection, ornamental value as well as each maintenance, it is widely used for housing, hospital, school, factory, hotel, and restaurant decoration.

This line features of easy operation and high technical, which is for producing different colors pattern.

Product thickness is 2-3mm;width is 2000mm.

PVC Homogeneous Heart Flooring Leather Production Line Main technical specification

| Model | Product width | Product thickness | Capacity |

| JWTZ-2000 | 2000mm | 2-3mm | 3000m²/d |

PVC Homogeneous Heart Flooring Leather Production Line Application

LVT Soft Floor Extrusion Line

LVT soft composite floor production line by extruder extrusion floor base material, then through a set of six roller for base material and printing layer composite machine, wear-resisting layer, layer of compoundat the same time, through the rolling tension, wear-resisting layer accurate control of preheating, to put the volume not wrinkle, does not shrink, deformation, extrusion compound high production efficiency, product quality is stable.

LVT Soft floor Extrusion Line Main technical specification

| Model | Products width | Products thickness | Capacity |

| JWTZ- -2000 | 2000mm | 2- 3mm | 3000m²/d |

LVT Soft floor Extrusion Line Applicaiton

PVC homoegeneous LVT SPC WPC floor extrusion line

SPC Floor Extrusion Line

SPC Stone plastic extrusion line is PVC as base material and extruded by extruder, then get through four roll calendars, separately put PVC color film layer+PVC wear-resistance layer+PVC base membrane layer to be pressed and pasted together at one time progress. Simple process, complete the paste that depend on heat, without glue.

SPC Stone-plastic environmental floor extrusion line advantage

1. Waterproof and moistureproof, it can fundamentally solve the wooden product problems like easily be rotted and dilated deformation after absorbing water or affected with wet environment. Therefore, our company's WPC floor can be used in this kind of environment which the traditional wood product cannot.

2. Colorful, many colors are optional. There are natural wooden feeling and wooden texture, and also you can choose the color you need according to your personality.

3. Environmental protection , non- pollution, pollution-free, recycle. The products do not contain benzene and formaldehyde, it's a environmental products, recyclability reduce useage of wood, and that is suitable for the sustainable development of national policy and it also benefits society.

4. Good fireproofing. It can stop fire effectively, fire rating reach level B1, when the fire touch products, the fire will put out immediately, and do not produce any toxic gas.

5. Easy for installation, convenient for wok, simple construction ways, save installed time and fees.

6. Not cracking, not expand, not out of shape, do not repair and maintain, easy to clean, save after-repair and after-maintain fees.

SPC floor extrusion line Main technical specification

| Model | Product width | Product thickness | Capacity | Main motor power |

| 80/156 | 1050 | 3-8mm | 400-500KG/H | 75KW |

| 92/188 | 1220 | 3-8mm | 800-1000KG/H | 110KW |

| 110/220 | 1220 | 3-8mm | 1200-1400KG/H | 160KW |

SPC floor extrusion line Applicaiton

PVC homoegeneous LVT SPC WPC floor extrusion line

WPC (PE&PP) Wood-Plastic Floor Extrusion Line

WPC (PE&PP) Wood-Plastic Floor is that the wood-plastic composite materials complete in different equipments of mixing, from play, extruding products, mixing the raw material in a certain formula, forming wood-plastic particles in the middle, and then squeezing out products.

And nowadays, the two-step way is used currently, application of a wider general use dual-coneor two-extruder extruder granulation, and then double-cone or single screw extruder extrusion products, mainly used in floor indoor or outdoor, parapets, tray, such as WPC (PE&PP) plastic extrusion products.

WPC (PE&PP) Wood-Plastic Floor Extrusion Line Main technical specification

| Model | Screw specification(mm) | Power of main motor(KkW) | Output(kg/h) |

| 5IZ65 | 65/132 | 37 | 150-180 |

| SJZ72 | 72/152 | 45 | 125-300 |

| SJZ80 | 80/156 | 55 | 200-350 |

WPC (PE&PP) Wood-Plastic Floor Extrusion Line Application

PVC homoegeneous LVT SPC WPC floor extrusion line

Video

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

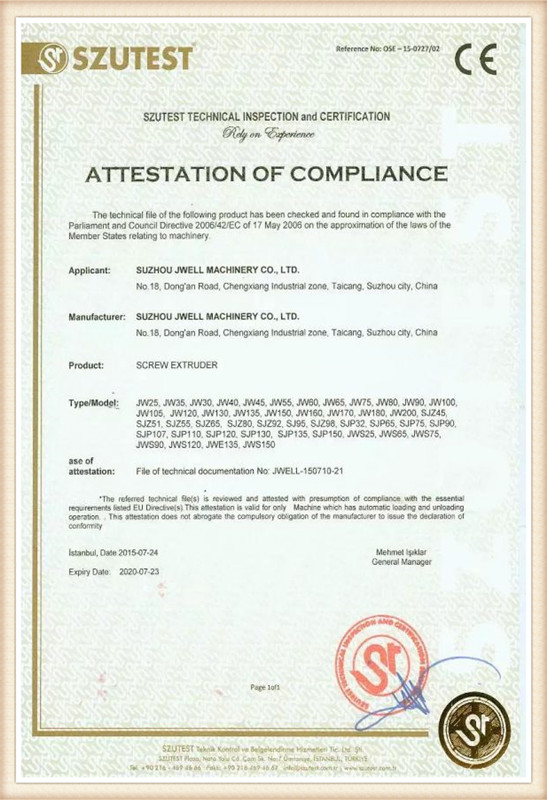

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~